Cycling Duty

Rapidly changing electric power markets are imposing new challenges – from reduced fuel and electricity prices to a growing number of green energy mandates – on owners and operators of fossil-fired generating facilities.

Few companies face this array of challenges more directly than Princeton, N.J.-based NRG. The company’s generating portfolio consists of coal, natural gas, nuclear, solar, and wind facilities – all of which represent some 46,000 MW of capacity. Moreover, the company operates in a range of U.S. markets that’s as diverse as its portfolio.

Fortnightly’s PowerProfit spoke recently with NRG Energy’s Executive Vice President and Chief Operating Officer Mauricio Gutierrez about the steps the company is taking to ensure its power generation assets remain competitive in today’s fast changing U.S. electric power sector.

PowerProfit: How do you go about evaluating your fleet – deciding which units will be upgraded and when, and which units will be curtailed or even shut down?

PowerProfit: How do you go about evaluating your fleet – deciding which units will be upgraded and when, and which units will be curtailed or even shut down?

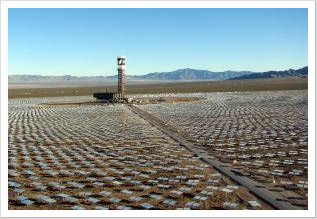

Gutierrez: That’s a complicated question because our power generation business is so diverse. We’re in many U.S. markets and because of that, we own a variety of generation technologies – nuclear, coal, and natural gas assets, and renewable assets like wind and solar generation. So the short answer is we evaluate each asset in terms of technology, its location, fuel use, and merit order.

PowerProfit: OK, let’s start with coal. With a growing number of coal plants being retired, what are some of the biggest challenges to keeping your plants on line? What’s your take on the future of these plants specifically and on coal-fired generation in general, especially with the possibility of new EPA mandates on the horizon?

Gutierrez: The outlook is obviously challenging. Small, environmentally uncontrolled units will continue to exit the market. For many, it’s not a matter of if, but when. What’s interesting is we as an industry always thought environmental regulations would be the catalyst for that, but it’s the low price of natural gas. When natural gas hit $2 MMBtu, it was the “a-ha moment” for owners of these small coal units. They were no longer making money. And now some of the larger coal units – even those with the necessary environmental controls – are exiting the market because they’re not in a prime location.

In the PJM marketplace we have a generation portfolio comprised mostly of baseload coal-fired generation. With gas at $3 or $4 MMBtu, gas-fired combined cycle plants have become the dominant baseload resource. As a result, we now view our PJM portfolio as providing system adequacy as opposed to traditional baseload energy supply. And we are in the process of re-calibrating our O&M program to make sure these units remain competitive – not just in terms of producing electricity, but providing the capacity that the system needs during peak load situations.

PowerProfit: So how do you go about that?

Gutierrez: You have to completely re-think the way you operate these assets. In the past coal-fired baseload units were running 24/7. Now many are operating like 12- to 14-hour notice peakers. The system operator anticipates a heat wave and notifies the coal plant that it’s going to need that capacity. The unit is brought on-line, runs through the weather period, and then it’s brought back down. That’s a complete change in culture.

We view it as a sort of block generation strategy. You run a unit Monday thru Friday and then, because the weekend demand doesn’t look very good, bring it down and then bring it back up again on Monday. Obviously I’m generalizing but you get the point. In today’s market, there are periods of time when you want to make the plant available because the economic incentive is there. Other times there might be some economic margin, but it doesn’t make sense to place all that wear and tear on the unit.

So we’re changing the operating protocols on many of our coal units to account for cycling duty. When you bring a unit from maximum capacity to minimum generation levels in a controlled, orderly fashion, the wear and tear associated with cycling is reduced significantly. I’m not talking about chasing price with these units. This is a conscious decision to ensure you bring a unit up or down in an orderly fashion.

So we’re changing the operating protocols on many of our coal units to account for cycling duty. When you bring a unit from maximum capacity to minimum generation levels in a controlled, orderly fashion, the wear and tear associated with cycling is reduced significantly. I’m not talking about chasing price with these units. This is a conscious decision to ensure you bring a unit up or down in an orderly fashion.

PowerProfit: How is that affecting the competitiveness of your coal operations?

Gutierrez: When you look at our generation portfolio, many of our coal assets are in locations that provide a price premium relative to the rest of the market. So we believe our large coal units will survive. Yes, they’re under significant pressure, but we believe there’s a light at the end of the tunnel.

As you know, there’s a major correlation between natural gas prices and electricity prices. Natural gas tends to be the marginal fuel that sets the price of electricity, so if natural gas prices increase, then the profitability of those coal units will increase with it.

Natural gas is a cyclical commodity. Obviously I can’t tell you when it’s going to rebound, but we’re starting to see industrial plants – substantial natural gas consumers – moving into the U.S. Add the possibility of LNG exports, and we think natural gas prices will eventually trend upward. We want a portfolio that can take advantage of that.

Natural gas is a cyclical commodity. Obviously I can’t tell you when it’s going to rebound, but we’re starting to see industrial plants – substantial natural gas consumers – moving into the U.S. Add the possibility of LNG exports, and we think natural gas prices will eventually trend upward. We want a portfolio that can take advantage of that.

We have coal-fired units, such as Parish (2,504, MW, Thompsons, Texas), Limestone (1,689 MW, Jewett, Texas), and Morgantown (1,477 MW, Newburg, Md.), and we want to reduce their operating costs now so that we not only survive but are ready to take advantage of the market when it turns around. When that happens, these plants will be more profitable because we’ll be generating electricity at coal prices and selling at natural gas prices.

In the past, when gas was $10 MMBtu or more, you generated as many megawatt-hours as possible. Today we don’t need to chase every single MWh. We’ve also increased the focus on our O&M programs. We’ve placed a much greater emphasis on inspection and other maintenance activities so that when the recovery happens these plants are ready to take advantage of it.

PowerProfit: How about converting from coal to natural gas?

Gutierrez: We’re in the process of converting from coal to gas at our 732-MW Avon Lake (Ohio) and 330 MW New Castle (West Pittsburgh, Pa.) plants. Those are scheduled to be completed in May 2016. We’re also in the early stages of converting one of the units at the 1,496 MW Big Cajun II station in New Roads, La., to natural gas as well. I think you’re going to see that continuing industrywide.

PowerProfit: NRG just completed a natural gas repowering and modernization project at the El Segundo Energy Center in California. How does this project reflect your corporate strategy going forward?

Gutierrez: Actually, we just repowered two gas-fired plants in California – the 720 MW Marsh Landing Station in Pittsburg and the 550 MW El Segundo facility.

Gutierrez: Actually, we just repowered two gas-fired plants in California – the 720 MW Marsh Landing Station in Pittsburg and the 550 MW El Segundo facility.

At El Segundo, we retired a less efficient, gas-fired 335 MW steam boiler built in 1964 that relied on ocean water for cooling and replaced it with a new combustion turbine system that uses reclaimed water for air-cooled, combined-cycle operation. That reduced the plant’s overall water use by nearly 90 percent. The plant also uses 30 percent less gas per MW and can deliver more than half of its capacity in roughly 10 minutes, so it can support the state’s growing intermittent resources, particularly solar.

We have other repowering candidates across our fleet, including Mandalay, a 560 MW gas-fired plant in Oxnard, Calif. In the Northeast, we have the 404 MW gas-fired Astoria plant in Queens, N.Y., and other similar assets in the vicinity of New York City. There’s been a lot of discussion about the potential shutdown of nuclear facilities in that region, and if that turns out to be the case, Astoria and these other assets could be prime candidates for repowering.

PowerProfit: NRG is a major player in the renewable energy space. Will you continue to expand your holdings in that area?

PowerProfit: NRG is a major player in the renewable energy space. Will you continue to expand your holdings in that area?

Gutierrez: We have a first mover advantage in the renewable space, particularly with solar generation. The renewable portfolio standards (RPS) in the different states have given us the opportunity to grow that portfolio and generate a contracted stream of earnings. We are now one of the largest solar generators in the country and we’re going to continue developing that part of our business. But that’s going to be on the back of long-term contracts. For now, that’s the only way you can support the cost of renewable technologies.

---

ABOUT THE AUTHOR: Scott M. Gawlicki is Fortnightly's contributing editor, based in West Hartford, Ct.

ABOUT THE SOURCE: Mauricio Gutierrez has served as NRG’s executive vice president and chief operating officer since July 2010, overseeing the company’s plant, thermal, and commercial operations; environmental compliance; engineering, procurement and construction; and commodities trading. Previously he was NRG’s executive vice president, commercial operations and senior vice president, commodities trading.

Photos courtesy Mauricio Gutierrez, NRG Energy